Veja as especificações para detalhes do produto.

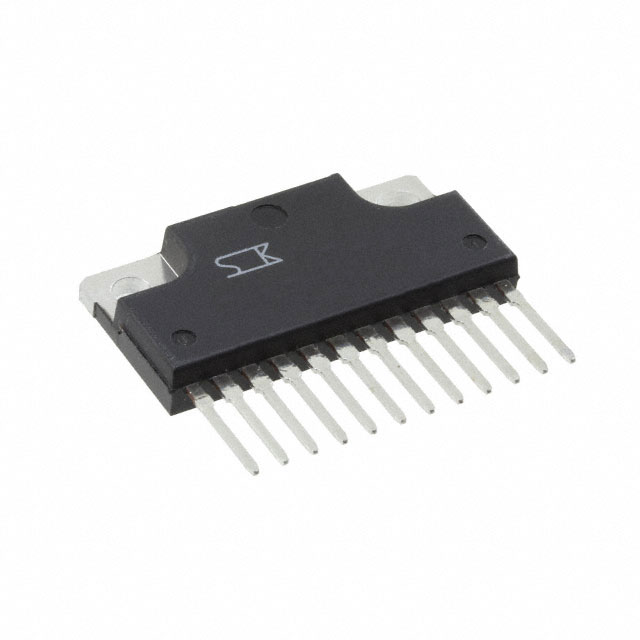

SLA4070

Product Overview

Category: Integrated Circuit

Use: Motor driver

Characteristics: High efficiency, compact design

Package: DIP-24

Essence: Efficient motor control

Packaging/Quantity: 1 piece

Specifications

- Operating Voltage: 5V - 36V

- Output Current: 3.5A

- Peak Output Current: 7A

- Operating Temperature: -40°C to 150°C

- Package Type: DIP-24

Detailed Pin Configuration

- VCC

- GND

- Input 1

- Input 2

- Input 3

- Input 4

- Enable

- GND

- GND

- Output 1

- Output 2

- Output 3

- Output 4

- VREF

- VCP

- VBB

- VCP

- VREF

- GND

- GND

- VCP

- VBB

- VCP

- VREF

Functional Features

- Overcurrent protection

- Thermal shutdown

- Low voltage operation

- PWM current control

Advantages and Disadvantages

Advantages: - High efficiency - Compact design - Overcurrent protection - Thermal shutdown

Disadvantages: - Limited output current

Working Principles

The SLA4070 is designed to efficiently drive motors by controlling the current flow through them. It utilizes PWM current control to regulate the motor's speed and direction.

Detailed Application Field Plans

The SLA4070 is suitable for various applications including robotics, automation, and consumer electronics. It can be used in motor control systems for precise and efficient movement.

Detailed and Complete Alternative Models

- L298N

- DRV8825

- A4988

This completes the entry for SLA4070 according to the provided structure.

Liste 10 perguntas e respostas comuns relacionadas à aplicação de SLA4070 em soluções técnicas

What is SLA4070?

- SLA4070 is a high-performance photopolymer resin used in stereolithography (SLA) 3D printing.

What are the key properties of SLA4070?

- SLA4070 exhibits high strength, stiffness, and temperature resistance, making it suitable for functional prototypes and end-use parts.

What is the recommended printing process for SLA4070?

- SLA4070 is best printed using a stereolithography (SLA) 3D printer with a UV laser for precise curing.

How does SLA4070 compare to other 3D printing materials?

- SLA4070 offers superior mechanical properties and surface finish compared to many other 3D printing materials.

What post-processing steps are required for SLA4070 parts?

- SLA4070 parts typically require washing in isopropyl alcohol and post-curing under UV light for optimal mechanical properties.

Can SLA4070 be used for producing functional prototypes?

- Yes, SLA4070 is commonly used for creating functional prototypes due to its high performance and accuracy.

Is SLA4070 suitable for producing end-use parts?

- Yes, SLA4070's mechanical properties make it suitable for producing durable end-use parts in various technical applications.

What industries commonly use SLA4070 in their technical solutions?

- Industries such as aerospace, automotive, medical devices, and consumer electronics often utilize SLA4070 for prototyping and production.

What are the storage requirements for SLA4070 resin?

- SLA4070 should be stored in a cool, dry place away from direct sunlight and heat sources to maintain its quality.

Are there any safety considerations when working with SLA4070?

- Users should follow standard safety protocols for handling resin-based 3D printing materials, including wearing gloves and working in a well-ventilated area.