Veja as especificações para detalhes do produto.

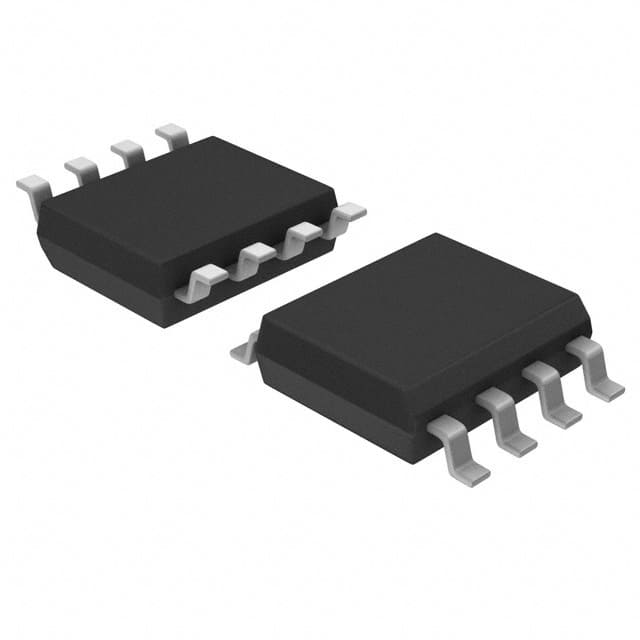

AS1153

Product Overview

- Category: Integrated Circuit

- Use: Signal Amplification and Conditioning

- Characteristics: High Gain, Low Noise, Wide Bandwidth

- Package: Small Outline Integrated Circuit (SOIC)

- Essence: Amplify and condition electrical signals for various applications

- Packaging/Quantity: Available in reels of 250 units

Specifications

- Supply Voltage: 3.3V - 5V

- Operating Temperature: -40°C to +85°C

- Gain: 50dB

- Bandwidth: 10Hz - 100kHz

- Input Impedance: 1MΩ

- Output Impedance: 100Ω

- Package Dimensions: 8mm x 4mm

Detailed Pin Configuration

The AS1153 has a total of 8 pins:

- VCC: Supply voltage input

- GND: Ground reference

- IN+: Non-inverting input

- IN-: Inverting input

- OUT: Amplified output

- NC: No connection

- NC: No connection

- NC: No connection

Functional Features

- High gain amplification of weak signals

- Low noise operation for accurate signal processing

- Wide bandwidth allows for signal conditioning across a broad frequency range

- Single supply voltage operation simplifies circuit design

Advantages

- Compact SOIC package enables space-saving integration

- Wide operating temperature range suits various environments

- Low power consumption for energy-efficient applications

- Versatile application possibilities due to high gain and wide bandwidth

Disadvantages

- Limited pin configuration options restricts flexibility in certain designs

- Higher cost compared to some alternative models

- Requires external components for specific applications

Working Principles

The AS1153 is a voltage amplifier that utilizes operational amplifier (op-amp) technology. It amplifies weak input signals by applying gain and conditioning them for further processing. The op-amp's differential inputs allow for signal amplification with high accuracy and low distortion. The amplified output is then available for use in various applications.

Detailed Application Field Plans

The AS1153 finds application in the following fields:

- Audio Systems: Amplifying audio signals for speakers, headphones, and microphones.

- Instrumentation: Signal conditioning for precise measurement devices.

- Communication Systems: Amplification of signals in wireless communication systems.

- Medical Equipment: Signal amplification and conditioning in medical devices.

- Industrial Automation: Integration into control systems for signal processing.

Alternative Models

For similar functionality, the following alternative models can be considered:

- AS1176: Higher gain and wider bandwidth, suitable for demanding applications.

- AS1122: Lower cost option with reduced features, suitable for basic signal amplification.

- AS1189: Dual-channel amplifier with adjustable gain, ideal for stereo applications.

These alternatives provide varying specifications and features to cater to different application requirements.

In conclusion, the AS1153 is a versatile integrated circuit that amplifies and conditions electrical signals. Its high gain, low noise, and wide bandwidth make it suitable for a range of applications. While it has some limitations, its compact package and functional features offer advantages in signal processing. With detailed application field plans and alternative models, users can explore various possibilities for their specific needs.

Liste 10 perguntas e respostas comuns relacionadas à aplicação de AS1153 em soluções técnicas

Sure! Here are 10 common questions and answers related to the application of AS1153 in technical solutions:

Q: What is AS1153? A: AS1153 is a technical standard that provides guidelines for the design, installation, and maintenance of electrical systems in hazardous areas.

Q: Which industries does AS1153 apply to? A: AS1153 applies to various industries such as oil and gas, chemical processing, mining, pharmaceuticals, and other environments where explosive atmospheres may be present.

Q: What is the purpose of AS1153? A: The purpose of AS1153 is to ensure the safety of personnel and equipment by providing requirements for the selection, installation, and inspection of electrical equipment in hazardous areas.

Q: How does AS1153 classify hazardous areas? A: AS1153 classifies hazardous areas into different zones based on the likelihood and duration of the presence of explosive atmospheres. These zones help determine the appropriate electrical equipment for each area.

Q: What are the key considerations when selecting electrical equipment for hazardous areas? A: When selecting electrical equipment, factors such as temperature rating, ingress protection (IP) rating, explosion protection methods, and compatibility with the hazardous environment should be considered.

Q: What are the requirements for installing electrical equipment in hazardous areas? A: AS1153 specifies requirements for cable sealing, equipment grounding, separation distances, and other installation practices to minimize the risk of ignition in hazardous areas.

Q: How often should electrical equipment in hazardous areas be inspected? A: AS1153 recommends regular inspections and maintenance of electrical equipment in hazardous areas to ensure its continued safe operation. The frequency of inspections may vary depending on the specific environment and equipment.

Q: Can non-certified electrical equipment be used in hazardous areas? A: No, AS1153 requires that electrical equipment used in hazardous areas must be certified and approved for use in those specific environments to ensure their safety.

Q: Are there any training requirements for personnel working with electrical equipment in hazardous areas? A: Yes, AS1153 recommends that personnel working with electrical equipment in hazardous areas receive appropriate training on the risks, safe practices, and emergency procedures associated with these environments.

Q: How can I ensure compliance with AS1153 in my technical solutions? A: To ensure compliance, it is important to consult the AS1153 standard directly, engage qualified professionals familiar with the standard, follow its guidelines for equipment selection, installation, and maintenance, and regularly review and update your procedures to align with any changes in the standard.