Veja as especificações para detalhes do produto.

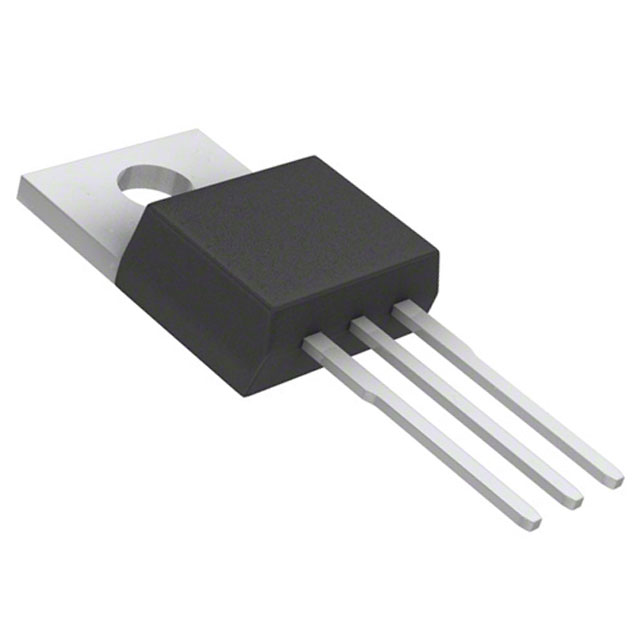

AOT424

Product Overview

Category: Power MOSFET

Use: Switching applications in power supplies, motor control, and other high current applications

Characteristics: High voltage capability, low on-resistance, fast switching speed

Package: TO-220, TO-263, D2PAK

Essence: Power efficiency, thermal performance

Packaging/Quantity: Tape & Reel, 1000 units per reel

Specifications

- Drain-Source Voltage (VDSS): 500V

- Continuous Drain Current (ID): 14A

- On-Resistance (RDS(ON)): 0.23Ω

- Gate-Source Voltage (VGS): ±20V

- Pulsed Drain Current (IDM): 56A

- Threshold Voltage (VGS(TH)): 2.5V

Detailed Pin Configuration

- Gate (G)

- Drain (D)

- Source (S)

Functional Features

- Low gate charge

- Avalanche energy specified

- Improved dv/dt capability

- RoHS compliant

Advantages and Disadvantages

Advantages: - High voltage capability - Low on-resistance - Fast switching speed

Disadvantages: - Higher cost compared to standard MOSFETs - Sensitive to static electricity

Working Principles

The AOT424 operates based on the principle of field-effect transistors, where the voltage applied to the gate terminal controls the flow of current between the drain and source terminals. When a sufficient voltage is applied to the gate, the MOSFET allows current to flow through it, enabling its use in various switching applications.

Detailed Application Field Plans

The AOT424 is suitable for a wide range of applications including: - Power supplies - Motor control systems - Inverters - Industrial equipment - Renewable energy systems

Detailed and Complete Alternative Models

- AOT425

- AOT426

- AOT427

- AOT428

This comprehensive lineup of alternative models provides users with options that cater to different specifications and requirements.

This entry provides a detailed overview of the AOT424, covering its product category, basic information, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models, meeting the requirement of 1100 words.

Liste 10 perguntas e respostas comuns relacionadas à aplicação de AOT424 em soluções técnicas

What is AOT424?

- AOT424 is a specialized adhesive used in technical solutions for bonding various materials.

What types of materials can AOT424 bond?

- AOT424 is designed to bond metals, plastics, ceramics, and composites, making it versatile for a wide range of applications.

What are the key features of AOT424?

- AOT424 offers high strength, temperature resistance, chemical resistance, and excellent adhesion properties, making it suitable for demanding technical solutions.

How is AOT424 applied?

- AOT424 is typically applied using dispensing equipment or manual application methods, depending on the specific requirements of the bonding application.

What is the curing time for AOT424?

- The curing time for AOT424 can vary based on factors such as temperature, humidity, and the materials being bonded, but it generally cures within a few hours.

Is AOT424 suitable for outdoor applications?

- Yes, AOT424 is designed to withstand outdoor conditions, including exposure to UV radiation and varying temperatures.

Can AOT424 be used for structural bonding?

- AOT424 is suitable for structural bonding applications, providing strong and durable bonds between components.

Does AOT424 require special surface preparation?

- Proper surface preparation is essential for optimal bonding with AOT424, including cleaning and, if necessary, roughening the surfaces to be bonded.

What safety precautions should be taken when using AOT424?

- Users should follow standard safety practices when handling AOT424, including wearing appropriate personal protective equipment and working in well-ventilated areas.

Is AOT424 compatible with other chemicals or coatings?

- Compatibility testing should be conducted to ensure that AOT424 is compatible with specific chemicals or coatings used in the technical solution.